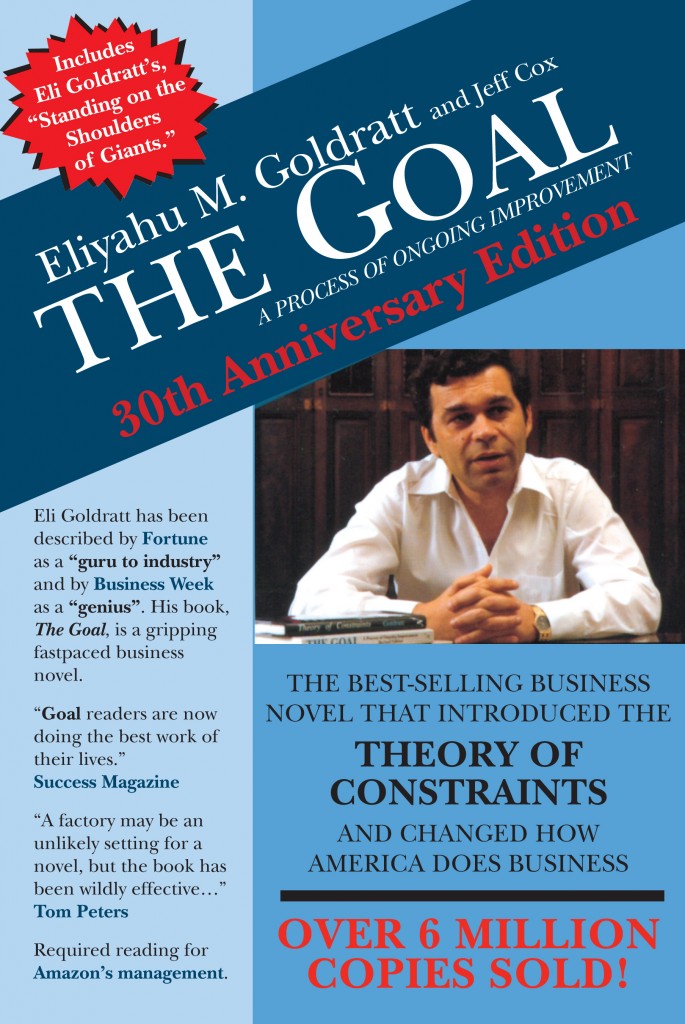

Presented in the form of a novel, this book explores concepts and thought patterns essential for enhancing the flow and productivity of a manufacturing plant. Productivity is defined as any action that brings us closer to our goal, which, in this context, should be associated with generating profits.

While cost-effective purchasing, hiring skilled personnel, and producing quality products are all important components, they are merely means to achieve the ultimate goal of making money.

Organizations should be assessed by three key metrics:

- Throughput: The rate at which the system generates money through sales (the number of products sold each day).

- Inventory: The total amount of money invested in purchasing items intended for sale.

- Operational expenses: The total amount of money the system expends to transform inventory into throughput.

The book uses the analogy of a boy scout hike to visualize these concepts of flow. Throughput can be likened to the trail covered by the entire troop, with its pace determined by the slowest member. Inventory represents the length of the troop, while operational expenses represent the collective effort required to traverse the trail and convert troop length into throughput. In this scenario, the constraint, symbolized by the slowest boy scout, sets the throughput for the entire system.

The steps to improve flow and processes are as follows:

- Identify the system’s constraint.

- Determine how to exploit the constraint.

- Subordinate everything else (including other workstations) to match the pace of the constraint.

- Elevate the system’s constraint by adding capacity or eliminating unnecessary work at the constraint.

- If a constraint is eliminated in the previous step, return to step 1.

Identifying the system constraint may require looking beyond the capacity of each machine, focusing on where Work-in-Progress (WIP) accumulates and where expedited efforts are commonly needed to locate missing parts.

“Balance flow, not capacity” Eliyahu M. Goldratt

To exploit the constraint effectively, it’s crucial to ensure they are not idle or processing defective units that do not contribute to sales (e.g., spare parts).

Subordinating everything else involves ensuring that other workstations prioritize producing parts that need to pass through the constraint.

The Goal serves as a valuable reminder that achieving operational excellence requires more than just adhering to conventional metrics; it necessitates a fundamental shift in mindset. Relying on traditional measurements can create a misleading sense of control, diverting attention from an organization’s true objectives.

While resource efficiency metrics offer a superficial illusion of control, the true transformation lies beneath the surface, much like the substantial mass of an iceberg hidden beneath the waterline.

Traditional accounting measures can often be misleading. Reducing inventory may appear as a loss in assets, while decreasing material release to increase throughput can lead to idle time at non-bottleneck areas and decreased local efficiencies. Reducing batch sizes can enhance throughput but may increase setup time and overhead costs per part.

To improve flow, the mindset should shift from solely focusing on cost reduction to optimizing Throughput, followed by Inventory. Striking the right balance between workstation capacity and buffers upstream from the constraint is critical to prevent constraint starvation.

Some selected Take away

Our experiences at Think Flow from working with software development flows has many similarities with flows described in the book.

Understanding the complete value stream is a common challenge in the organizations we engage with. Central to this is measuring true throughput, as emphasized by Goldratt—highlighting the importance of the system’s ability to generate revenue. Moreover, we’ve recognized the criticality of prioritizing quality to prevent throughput loss due to processing defective units.

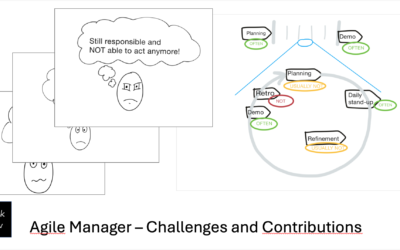

One recurring observation involves the misconception of resource optimization. Many organizations tend to focus on constantly utilizing all available resources, often seeing certain departments, such as IT, as mere cost centers. However, the book underscores the necessity of shifting from local efficiency to a systemic view of the entire value stream for effective operations.

The common equation of capacity solely with the number of people and their time available fails to provide an accurate forecast of delivery capacity. The need to understand actual throughput, e.g. in terms of number of features over a period of time, is essential to make realistic forecasts and use capacity to inform business decisions.

Identifying and addressing actual bottlenecks is another shared challenge. Unlike the physical constraint depicted in the book, in software development, these bottlenecks are less visible. Thus, visualizing and understanding them becomes imperative for improving delivery capabilities.

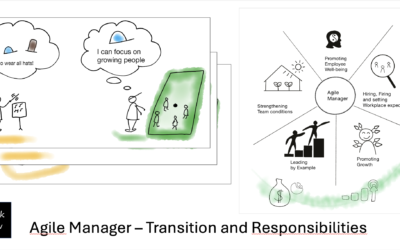

Cultural transformation stands out as a crucial aspect highlighted by the book. Establishing a culture supporting continuous improvement is essential in reducing bottlenecks and fostering an environment where employees feel motivated to identify improvement opportunities. However, this shift in organizational culture remains challenging, often limiting discussions to local improvements rather than systemic changes that could yield more significant results.

Finally, the concept of reducing inventory to enhance efficiency and increase revenue is essential. Whether it’s physical inventory or finalized functionality not deployed in software development, the value does not reach customers and revenue is lost.

Introducing continuous deliveries ensures that functionalities are promptly benefiting customers, thereby optimizing revenue streams.

In essence, “The Goal” resonates with our experiences, showcasing parallels between the book’s principles and the challenges we encounter in various industries, urging a shift in mindset and practices for improvements of the entire system.

0 Comments